Product Name:aluminum honeycomb panel

Brand:Guangdong Reinalite Industrial Co.,Ltd

Material:Anodic Aluminum Oxide

Color:customized design,choosed from RAL catalog

Color:customized design,choosed from RAL catalog

Pattern:Customized Available.

Length:according your detail drawings

Process Equipment:CNC punching/ engraving machine

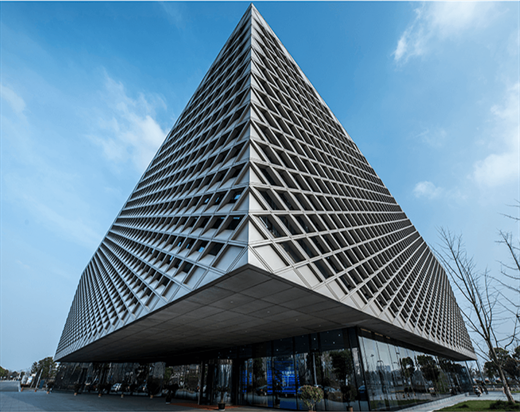

Application:Exterior facade curtain wall/outdoor decoration

Warranty:Up to15 Years based on different coating

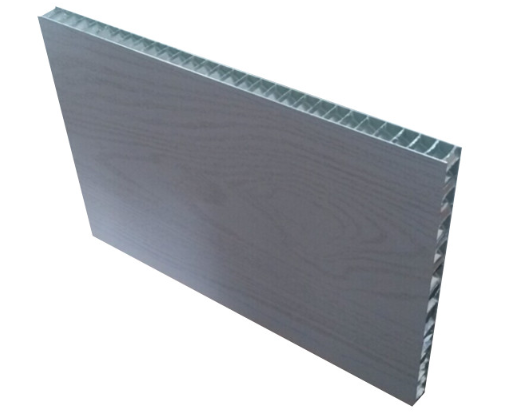

Monthly Capacity:50000 square meters

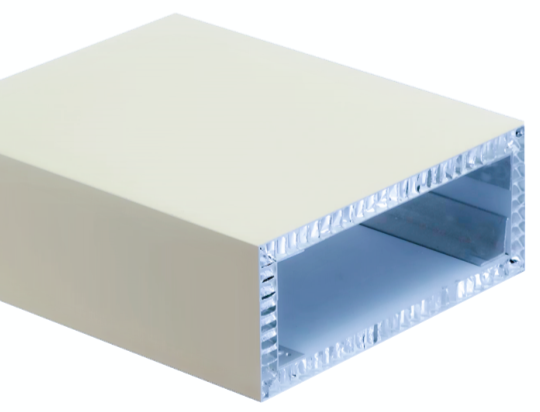

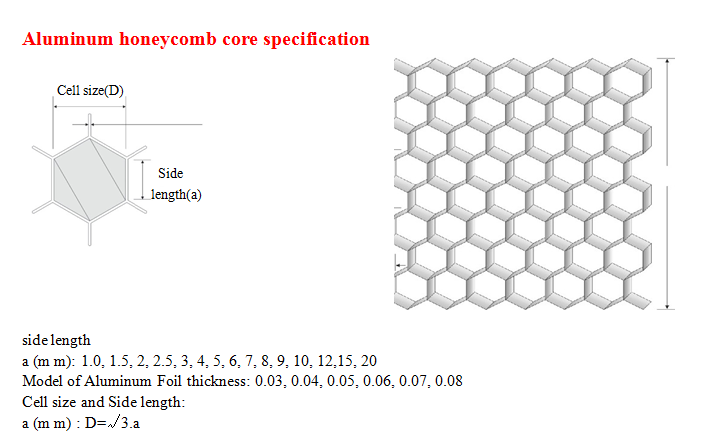

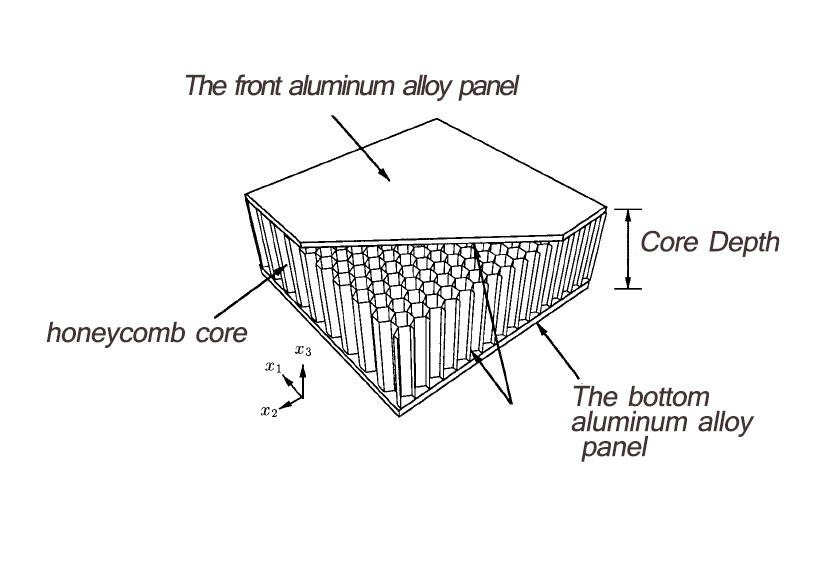

The upper and lower bottom plates and panels of the aluminum honeycomb panel are mainly made of high-quality 3003H24 alloy aluminum panels with a thick and light honeycomb core sandwiched between them. The panel and the sandwich core are cemented into a whole rigid structure by an adhesive. The surface treatment of the panel can be fluorocarbon, roll coating, thermal transfer, wire drawing, and oxidation; aluminum honeycomb panels can also be laminated with fire-resistant panels, stone materials, and ceramics; the thickness of the aluminum panels is 0.4mm-3.0mm. The core material adopts hexagonal 3003 aluminum honeycomb core, the thickness of aluminum foil is 0.04~0.06mm, and the side length models are 5mm, 6mm, 8mm, 10mm, 12mm.

Because the bottom plate and panel of the honeycomb sandwich structure are very thin and light, the sandwich is made of porous material with low density, and the aluminum alloy itself is light metal; therefore, the weight reduction effect of the sandwich structure material composed of honeycomb aluminum core and aluminum panel is particularly obvious; aluminum honeycomb Due to its light weight, high strength, high rigidity and many other advantages, panels have been widely used in building exterior wall decoration, furniture, carriages, etc.

Aluminum honeycomb panel structure:

Aluminum honeycomb core: using aluminum foil as the base material, it is composed of many dense honeycombs that are confined to each other, which can disperse and bear the pressure from the plate direction, so that the panel is evenly stressed, and ensures its strength to withstand pressure and maintains a large area. High flatness

◆ Coated aluminum panels: Fluorocarbon exterior wall panels, all imported from Japan Daikin coated panels, fluorocarbon content of more than 70%, fluorocarbon resin using American PPG fluorocarbon coating, with the best anti-acid, anti-alkali and anti-ultraviolet The irradiation function.

◆ Aluminum alloy plate: The aluminum plate produced by the Southwest Aluminum Plate Processing Plant is used, and the rust-proof aluminum plate meets the requirements of GB/3880-1997 standard. All aluminum plates are cleaned and chromized to ensure that the thermal composite bonding is flat and firm.

◆ Adhesive: The most important material of the aluminum honeycomb core is the adhesive for bonding the aluminum panel and the honeycomb die. The adhesive film of our company uses the polymer adhesive produced by DuPont of the United States and has a ten-year quality guarantee.

1. Light weight and high strength

2. High temperature resistance, severe cold resistance, no cracking

3. It can be processed arbitrarily and is easy to install

4. Class A1 fire performance

5. Surface high temperature spraying and oxidation treatment

6. Green and environmental protection, 100% recycling

(1) Exterior wall hanging board of building curtain wall

(2) Interior decoration project

(3) Billboard

(4) Shipbuilding

(5) Aviation manufacturing

(6) Indoor partition and merchandise display stand

(7) Commercial transport vehicles and container truck bodies

(8) Buses, trains, subways and rail transit vehicles

(9) For the modern furniture industry with strict environmental protection requirements, using aluminum honeycomb panels as furniture processing materials is a good material choice in the new century. Its completely non-toxic green quality allows furniture manufacturers to process When it comes to furniture, unnecessary environmental protection procedures are eliminated; in addition, aluminum honeycomb panels can be diversified, such as solid wood, aluminum panels, gypsum boards, and natural marble materials. They can all be made into honeycomb panels, and the material selection is convenient.

(10) Aluminum honeycomb panel partition: The emergence of aluminum honeycomb panel partition breaks the traditional partition mode. With its noble, fresh and magnificent style, it has won the market share of medium and high-end office spaces.